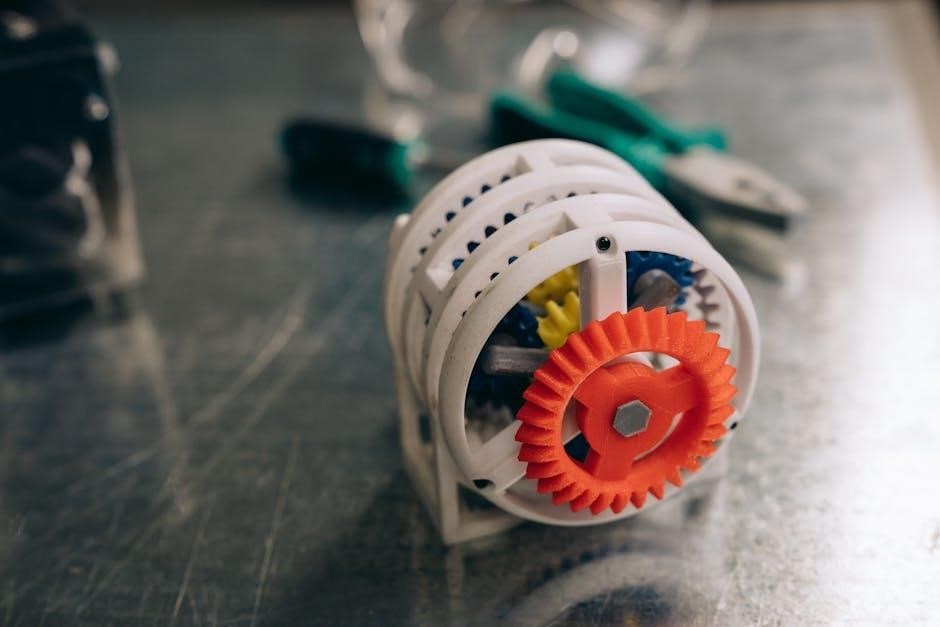

Gears, essential power transmission components, come in diverse types – spur, helical, bevel, worm, and rack. Understanding these types is crucial for effective engineering design.

Gear classification considers tooth form and peripheral velocity, impacting application suitability. Common gear types offer unique advantages for various mechanical systems.

Selecting the correct gear type optimizes performance, efficiency, and longevity within a given application, making knowledge of gear types paramount.

What are Gears?

Gears are fundamental mechanical components possessing toothed wheels designed to transmit rotational motion and torque. They function by meshing teeth, effectively transferring power between shafts. These engineered components are vital across numerous industries, from automotive to aerospace and beyond.

Essentially, gears modify speed, torque, and direction of a power source. Different gear types – spur, helical, bevel, and worm – achieve this through varying tooth geometries and arrangements. Understanding their core function is key to appreciating their diverse applications and selecting the optimal gear for a specific task;

Importance of Gear Selection

Gear selection is paramount for optimal system performance and longevity. Choosing the incorrect gear type can lead to inefficiencies, premature wear, and even catastrophic failure. Factors like load, speed, noise requirements, and space constraints heavily influence this critical decision.

Proper gear choice directly impacts torque transmission, speed ratios, and overall system efficiency. Considering these elements ensures reliable operation and minimizes energy loss. A well-selected gear maximizes power transfer while maintaining acceptable noise levels and extending component lifespan, ultimately reducing operational costs.

Spur Gears: The Fundamentals

Spur gears, the most common gear type, feature straight teeth cut parallel to the axis. They efficiently transmit power between parallel shafts, offering simplicity.

Characteristics of Spur Gears

Spur gears exhibit several defining characteristics. Their straight, parallel teeth make them relatively simple and inexpensive to manufacture. They efficiently transmit power between parallel shafts, making them widely applicable. However, spur gears are known for generating noise during operation due to the abrupt engagement of teeth.

These gears are best suited for lower-speed applications and transmit power smoothly when properly lubricated. The tooth profile, often involute, ensures constant velocity ratios. Spur gears are limited by their inability to handle high loads compared to helical designs.

Applications of Spur Gears

Spur gears find extensive use in numerous applications due to their simplicity and cost-effectiveness. They are commonly found in gearboxes, power tools, and various machinery where parallel shaft power transmission is required. Automotive transmissions often utilize spur gears in lower gear ratios.

Household appliances like washing machines and clocks also frequently employ spur gears. Their straightforward design makes them ideal for applications demanding moderate speeds and loads. They are also prevalent in industrial equipment, contributing to efficient mechanical operation across diverse sectors.

Advantages and Disadvantages of Spur Gears

Spur gears boast simplicity in design and manufacturing, leading to lower production costs and high efficiency in power transmission. They are reliable and operate with minimal noise at moderate speeds. However, spur gears generate significant noise at higher velocities due to abrupt tooth engagement.

They are also limited to parallel shaft configurations and experience higher tooth stress compared to helical designs. Their load-carrying capacity is relatively lower, making them less suitable for heavy-duty applications requiring substantial torque transmission.

Helical Gears: An Overview

Helical gears, cylindrical with angled teeth, offer smoother, quieter operation and higher load capacity than spur gears. They excel in high-speed applications.

Helical Gear Design and Features

Helical gears distinguish themselves through their angled teeth, forming a helix around the gear’s circumference. This design allows for gradual tooth engagement, resulting in smoother and quieter operation compared to spur gears.

Key features include a higher load-carrying capacity and the ability to transmit power between parallel or non-parallel shafts. The helix angle significantly influences performance, impacting axial thrust and noise levels. Careful consideration of this angle is vital during design.

Furthermore, helical gears often require thrust bearings to manage axial forces generated by the angled teeth, adding complexity to the overall system.

Applications of Helical Gears

Helical gears find extensive use in applications demanding high speed and quiet operation, such as automotive transmissions. Their ability to handle substantial loads makes them ideal for industrial machinery like gearboxes and pumps.

They are commonly employed in applications where noise reduction is critical, including power tools and printing presses. The smoother engagement minimizes vibration and acoustic emissions.

Furthermore, helical gears are prevalent in applications requiring high efficiency and durability, contributing to reliable performance in diverse mechanical systems across various industries.

Noise Reduction in Helical Gears

Helical gears inherently exhibit reduced noise levels compared to spur gears due to their gradual tooth engagement. This progressive contact minimizes impact and vibration, resulting in quieter operation;

The angled teeth distribute the load over a larger area, lessening the instantaneous force and associated noise. Overlap ratio, a key design parameter, further enhances smoothness and diminishes noise generation.

Proper lubrication and precise manufacturing tolerances also contribute significantly to noise reduction, ensuring optimal performance and a quieter mechanical system overall.

Bevel Gears: Angular Power Transmission

Bevel gears transmit power between shafts intersecting at an angle, utilizing angled teeth for efficient torque transfer. They are crucial for non-parallel applications.

Types of Bevel Gears (Straight, Spiral, Zerol)

Straight bevel gears possess straight teeth, are simpler to manufacture, and are cost-effective, though generally noisier in operation. Spiral bevel gears feature curved, helical teeth, offering smoother, quieter performance and higher load capacity, but are more complex to produce.

Zerol bevel gears represent a specialized type; their teeth are curved and designed for minimal axial thrust, making them suitable for high-speed applications where axial loads are undesirable. Each type caters to specific needs regarding noise, load, and manufacturing complexity.

Applications of Bevel Gears

Bevel gears excel in transmitting power between shafts intersecting at angles, commonly found in automotive differentials, allowing wheels to rotate at different speeds during turns. They’re also prevalent in hand drills, where they change the axis of rotation from the motor to the drill bit.

Furthermore, bevel gears are utilized in various industrial machinery, including power tools, helicopter transmissions, and printing presses, due to their ability to handle significant torque and provide reliable angular power transfer. Their versatility makes them a staple in mechanical engineering.

Manufacturing Considerations for Bevel Gears

Bevel gear manufacturing demands precision due to their complex, angled tooth geometry. Processes like gear shaping, milling, and grinding are employed, requiring specialized tooling and skilled operators. Accurate tooth alignment and surface finish are critical for smooth operation and longevity.

Heat treatment is essential to achieve desired hardness and wear resistance. Inspection utilizes advanced techniques to verify tooth accuracy and ensure proper meshing with mating gears. Maintaining tight tolerances throughout the manufacturing process is paramount for optimal performance.

Worm Gears: High Ratio and Self-Locking

Worm gears excel at achieving high gear ratios in a compact space, often exhibiting self-locking characteristics, preventing back-driving.

Worm Gear Geometry and Operation

Worm gears comprise a worm – a screw-like wheel – meshing with a worm wheel, resembling a helical gear. The worm’s threads engage with the worm wheel’s teeth, transmitting motion.

Operation involves the worm rotating, driving the worm wheel. This configuration allows for significant speed reduction and torque multiplication. The geometry dictates efficiency; a larger lead angle generally improves efficiency but reduces the gear ratio.

Key parameters include the worm’s pitch, number of starts, and pressure angle, all influencing performance. Understanding these geometric aspects is vital for proper design and application.

Applications of Worm Gears

Worm gears excel in applications demanding high gear ratios and compact designs. They’re prevalent in speed reducers, steering mechanisms, and conveyor systems, offering substantial torque amplification.

Their self-locking characteristic – preventing back-driving – makes them ideal for lifting devices, gate operators, and security systems. This feature enhances safety and control in critical applications.

Furthermore, worm gears find use in tuning instruments, medical equipment, and robotics, where precise motion control and reliable positioning are paramount. Their versatility ensures widespread industrial adoption.

Efficiency and Backlash in Worm Gears

Worm gears typically exhibit lower efficiency compared to other gear types due to significant sliding friction between the worm and wheel teeth. This friction generates heat and reduces power transmission effectiveness.

Backlash, the play between mating teeth, is also a concern in worm gear systems. Excessive backlash can lead to positioning inaccuracies and impact dynamic performance, requiring careful design considerations.

Lubrication plays a vital role in minimizing friction and wear, improving efficiency and reducing backlash. Proper material selection and precise manufacturing further mitigate these inherent limitations.

Rack and Pinion Gears: Linear to Rotary Motion

Rack and pinion gears convert linear motion into rotary motion, or vice versa, utilizing a gear of infinite diameter (the rack) meshing with a pinion gear;

Rack Gear Construction

Rack gears represent a fascinating segment of a gear with an infinite diameter, essentially a flat, toothed plate. These are commonly constructed with either spur or helical teeth, mirroring the corresponding gear types.

The tooth profile, often involute, ensures consistent meshing and smooth operation with the pinion gear. Manufacturing processes include hobbing, shaping, and milling, demanding precision to maintain accurate tooth geometry. Material selection, like steel or plastic, depends on load and application requirements.

Rack length is customizable, adapting to diverse linear travel needs in various mechanical systems.

Pinion Gear Design

Pinion gear design centers around a small cylindrical gear meshing with a larger rack gear, converting rotary motion into linear movement. Key design considerations include tooth profile – typically involute – ensuring smooth engagement and consistent transmission.

Material selection, often steel or engineered plastics, dictates strength and durability. Precise manufacturing, utilizing hobbing or shaping, is crucial for accurate tooth geometry and minimal backlash.

The pinion’s size and tooth count directly influence the mechanical advantage and speed ratio within the rack and pinion system.

Applications of Rack and Pinion Systems

Rack and pinion systems excel in converting rotational motion to linear force, finding widespread use in steering mechanisms of vehicles, providing precise directional control. They’re also integral to machine tools, enabling accurate positioning of cutting heads and tables.

Furthermore, these systems power gate openers, robotic joints, and various automation equipment. Their simplicity, efficiency, and relatively low cost make them a versatile choice across diverse industries.

Applications demanding precise linear movement benefit significantly from rack and pinion technology.

Hypoid Gears: Specialized Bevel Gears

Hypoid gears, a bevel gear variation, feature non-intersecting axes, enabling higher gear ratios and quieter operation, notably in automotive differentials.

Hypoid Gear Characteristics

Hypoid gears distinguish themselves through their unique geometry, featuring a spiral gear design with non-parallel and non-intersecting axes. This configuration allows for larger pinion diameters and smaller ring gear sizes, resulting in higher gear ratios within a compact space.

Unlike traditional bevel gears, hypoid gears don’t have coinciding axes, necessitating specialized lubrication to manage the sliding contact between teeth. This sliding action contributes to quieter operation compared to other gear types, making them ideal for applications demanding reduced noise levels.

However, the design also introduces complexities in manufacturing and requires precise alignment for optimal performance and longevity.

Applications of Hypoid Gears (Automotive Differentials)

Hypoid gears find their most prominent application within automotive differentials, enabling efficient power transfer to the wheels while accommodating changes in wheel speed during turns. Their design allows the pinion gear to drive a larger ring gear, providing the necessary torque multiplication for vehicle propulsion.

The non-intersecting axes of hypoid gears contribute to a lower driving position, enhancing vehicle stability and allowing for a lower vehicle center of gravity. This configuration is crucial for improved handling and reduced body roll during cornering maneuvers.

Furthermore, their quiet operation enhances passenger comfort within the vehicle cabin.

Lubrication Requirements for Hypoid Gears

Hypoid gears necessitate specialized lubrication due to their sliding contact, unlike simpler gear types. High-quality extreme pressure (EP) additives are crucial within the lubricant to prevent wear and scoring on the gear teeth surfaces during operation.

These additives form a protective film, minimizing friction and ensuring smooth, reliable power transmission. Proper lubricant viscosity is also vital, maintaining an oil film thickness capable of withstanding the high contact stresses inherent in hypoid gear systems.

Regular lubricant changes are essential for optimal performance and longevity.

Gear Classification by Velocity

Gears are classified by peripheral velocity: low, medium, and high velocity types. This categorization impacts material selection and design considerations for optimal performance.

Low Velocity Gears

Low velocity gears, characterized by slower rotational speeds, typically find application in heavy-duty machinery where torque transmission is paramount. These gears often utilize robust materials like cast iron or specialized steel alloys to withstand substantial loads.

Their design prioritizes durability over speed, making them ideal for applications such as industrial mills, mixers, and certain types of conveyor systems. The slower speeds also contribute to reduced noise and vibration levels, enhancing operational comfort and safety.

Precise lubrication is critical for low velocity gears to minimize wear and maintain efficiency, especially under high load conditions.

Medium Velocity Gears

Medium velocity gears represent a versatile category, balancing speed and torque capabilities for a wide range of applications. Commonly constructed from steel alloys, these gears offer a good compromise between durability and operational efficiency.

They are frequently employed in automotive transmissions, machine tools, and various industrial drive systems where moderate speeds and power transfer are required. Careful consideration of tooth profile and material selection is crucial for optimizing performance.

Effective lubrication and regular maintenance are essential for ensuring the longevity and reliability of medium velocity gears.

High Velocity Gears

High velocity gears are engineered for applications demanding rapid rotational speeds, often exceeding typical industrial standards. These gears necessitate precision manufacturing and robust materials – frequently specialized steel alloys – to withstand centrifugal forces and heat generation.

Applications include high-speed turbines, aerospace components, and certain types of power tools. Effective cooling and lubrication systems are paramount to prevent premature wear and failure.

Careful design considerations, including tooth profile optimization, are vital for ensuring reliable operation at elevated velocities.

Gear Tooth Profiles

Gear tooth profiles, like involute and cycloidal, define tooth shape and influence gear performance. The involute form is widely preferred for its consistent velocity ratio.

Optimal profile selection ensures smooth meshing, reduced noise, and maximized efficiency in power transmission systems.

Involute Tooth Profile Explained

The involute tooth profile is generated by unwinding a string from a rotating cylinder, creating a curve fundamental to modern gear design. This profile offers a constant velocity ratio during meshing, a critical advantage for consistent power transmission.

Its geometry ensures that the contact point between mating teeth moves along the line of action, minimizing sliding friction and wear. This characteristic contributes to higher efficiency and extended gear life. The involute form also simplifies manufacturing processes, allowing for precise and repeatable tooth creation.

Furthermore, it provides tolerance to center distance variations, enhancing gear system reliability.

Advantages of Involute Tooth Form

The involute tooth form boasts several key advantages. It maintains a constant velocity ratio, crucial for smooth power transfer, and minimizes sliding friction, enhancing efficiency and reducing wear. This profile’s geometry allows for some center distance variation without significantly impacting performance.

Manufacturing is simplified due to the standardized form, leading to cost-effectiveness and precision. The involute shape also inherently provides self-alignment capabilities, improving system reliability. Its consistent contact stress distribution extends gear lifespan.

Ultimately, it’s a robust and versatile tooth profile.

Other Tooth Profiles (Cycloidal)

While the involute form dominates, cycloidal tooth profiles represent an alternative. Historically used, cycloidal gears offer theoretical advantages in load distribution and reduced sensitivity to errors in center distance. However, they present significant manufacturing challenges.

Creating precise cycloidal teeth requires specialized tooling and processes, increasing production costs. They also exhibit higher sliding friction compared to involute gears, potentially reducing efficiency and increasing wear.

Consequently, cycloidal profiles are less common in modern applications.

Gear Terminology

Key terms define gear characteristics: module, pitch diameter, and pressure angle. Understanding gear ratio, backlash, and interference is vital for proper design and analysis.

Module, Pitch Diameter, and Pressure Angle

Module (m) represents the tooth size, calculated as pitch diameter divided by the number of teeth. Pitch diameter is the theoretical diameter where tooth contact occurs during meshing, crucial for gear calculations.

Pressure angle, typically 20 or 25 degrees, influences tooth strength and contact ratio. A higher pressure angle increases tooth strength but can raise sensitivity to center distance variations.

These parameters are interconnected and fundamental to gear design, ensuring proper meshing, load capacity, and smooth operation within a gear system. Accurate determination is essential.

Gear Ratio Calculation

Gear ratio, a fundamental aspect of gear systems, defines the relationship between the input and output speeds or torques. It’s calculated as the number of teeth on the driven gear divided by the number of teeth on the driving gear.

Alternatively, it can be determined by dividing the input speed by the output speed. A higher gear ratio results in increased torque and reduced speed, and vice versa.

Understanding gear ratio is vital for designing systems requiring specific speed or torque transformations, optimizing performance for diverse applications.

Understanding Backlash and Interference

Backlash, the play between mating gear teeth, arises from manufacturing tolerances and tooth clearances. Excessive backlash can cause inaccuracies and impact system responsiveness, particularly in precision applications.

Interference occurs when tooth profiles prevent proper meshing, potentially leading to jamming or damage. It’s crucial to design gears to avoid interference, considering factors like pressure angle and tooth form.

Minimizing both backlash and interference is essential for reliable and efficient gear train operation, ensuring smooth power transmission and longevity.

Materials Used in Gear Manufacturing

Gear materials include steel alloys for strength, plastic for quiet operation, and cast iron for damping. Material selection depends on application demands and cost.

Steel Alloys for Gears

Steel alloys dominate gear manufacturing due to their superior strength, durability, and ability to withstand high loads and temperatures. Common choices include carbon steels, alloy steels, and stainless steels, each offering specific properties.

Alloy steels, incorporating elements like chromium, nickel, and molybdenum, enhance hardness, toughness, and wear resistance. Heat treatment processes, such as hardening and tempering, further refine these characteristics. The specific alloy chosen depends on the gear’s intended application and operating conditions, balancing cost with performance requirements.

Plastic Gears and Their Applications

Plastic gears are increasingly utilized where low cost, quiet operation, and lightweight designs are prioritized. Materials like nylon, Delrin, and polycarbonate offer excellent wear resistance and self-lubricating properties, reducing the need for external lubrication.

These gears excel in low-to-moderate load applications, such as consumer electronics, toys, and small appliances. While not as strong as steel, plastic gears provide a cost-effective and efficient solution for numerous applications, particularly where noise reduction is critical.

Cast Iron Gears

Cast iron gears, traditionally favored for their cost-effectiveness and good damping capacity, are commonly found in applications requiring moderate strength and wear resistance. Gray cast iron’s inherent damping qualities minimize noise and vibration during operation, making them suitable for machinery where quietness is desired.

However, cast iron gears exhibit lower tensile strength compared to steel alloys. They are often used in lower-speed, high-torque applications like agricultural equipment and some industrial machinery, offering a balance between performance and affordability.

Gear Train Configurations

Gear trains – simple, compound, and epicyclic – dictate power transmission characteristics. Configuration selection impacts gear ratio, torque, and speed within a mechanical system.

These arrangements utilize various gear types to achieve desired output, optimizing performance for specific applications and engineering requirements.

Simple Gear Trains

Simple gear trains represent the most basic configuration, consisting of gears mounted on parallel shafts; Power transmission occurs sequentially from one gear to the next, altering speed and torque.

These trains utilize a single pair or multiple pairs of gears meshing directly, providing a straightforward method for mechanical advantage. The gear ratio is determined by the number of teeth on each gear involved in the transmission.

While offering simplicity, simple gear trains may require larger gear sizes to achieve substantial speed reductions or torque increases. They are commonly found in basic machinery and introductory mechanical systems.

Compound Gear Trains

Compound gear trains enhance mechanical advantage by utilizing multiple gears fixed on the same shaft, forming gear sets; This configuration allows for significant speed reduction or torque amplification within a compact space.

Unlike simple gear trains, compound systems employ intermediate gears to alter the direction of power transmission and achieve higher gear ratios. Each gear set contributes to the overall ratio, increasing design flexibility.

These trains are prevalent in applications demanding substantial torque, such as winches and heavy machinery, offering a more efficient solution than single-stage reductions.

Epicyclic Gear Trains

Epicyclic gear trains, also known as planetary gear systems, feature a unique configuration with gears rotating around a central sun gear. Planet gears mesh with both the sun and a fixed or rotating ring gear, enabling complex motion control.

These systems offer high gear ratios in a small package, making them ideal for applications like automatic transmissions and robotics. Varying which element is fixed alters the output speed and torque characteristics.

Epicyclic trains provide efficient power transfer and load distribution, contributing to their widespread use in demanding mechanical systems requiring precision and durability.